M.S.AMBROGIO

GROUP

We are a Group that, since the first company was founded in 1949, has developed innovative precision technology solutions to improve peoples' lives all over the world and we do so with the utmost respect for the environment and human values.

We want your life to move well

Our history

AN EVER-EVOLVING JOURNEY

1949

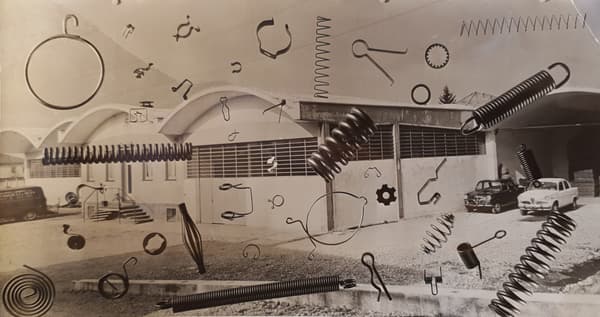

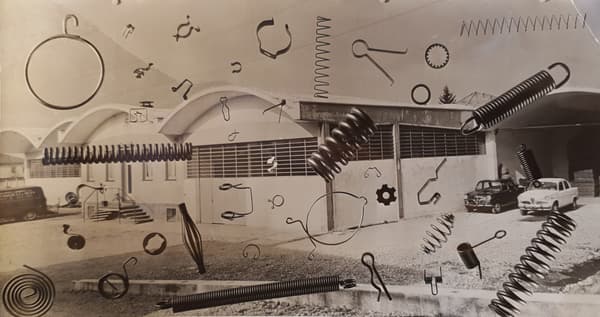

Aurelio Sangalli, his Father Mario and his brother-in-law Luigi Meda founded FIMIL (Fabbrica Italiana Molle in Laminato) and began producing springs and small metal parts in a little house on Via Cellini in Lecco.

1955

As the business gradually grew, a bigger workshop was needed. Production was moved to a larger and better organised facility in Via Marsala, Lecco, and the company changed its name to Sangalli e Meda snc. During this period, production and the model range were expanded, with capacity increasing to 500,000 items per day; some sectors grew significantly, particularly the automotive sector

1960

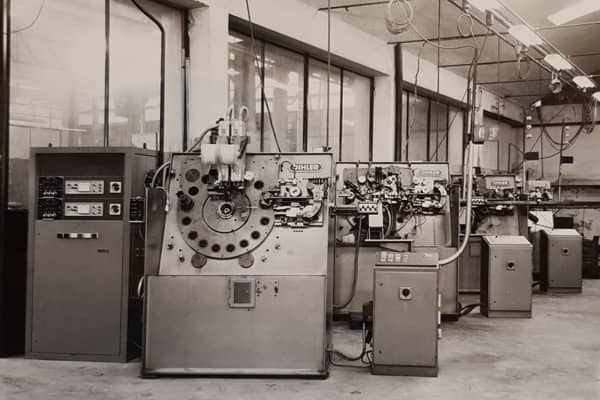

It became increasingly clear that the company needed to be restructured. Land was purchased on Via Valsugana in the Sant'Ambrogio area of Lecco and the new production facility was constructed. At this time the name of the company changed to Mollificio Sant'Ambrogio. The first Bihler machine was purchased.

1969

Acquisition of a company in Abbadìa (near Lecco) named Mollificio d’Abbadia, a manufacturer of compression and extension springs, and small metal parts.

The first welded contacts were produced with Bihler technology.

The first welded contacts were produced with Bihler technology.

1972

The company began automated production with the purchase of 5 Bihler welding units

1979

Mollificio Sant’Ambrogio established itself as one of the leading manufacturing companies in the country and the business strategy began to turn towards foreign markets as well. In the 1980s, representative offices opened in Spain and France and business relationships with foreign customers were established.

1981

New land was purchased in Cisano Bergamasco (near Bergamo)

1990

The second generation of the Sangalli family joined the company

1991

Aurelio Sangalli took over Springfix Gmbh, a well-established German company in the automotive industry, paying the symbolic sum of two German pfennigs.

1992

The current headquarters was built, bringing together the production of the Valsugana and Abbadìa sites.

1993

Luigi Meda left the corporate structure and the company remained under the ownership of the Sangalli family.

1999

Incorporation M.S.Ambrogio do Brasil

2001

Acquisition of Clamar, today fully integrated into M.S.Ambrogio, and known as the Chignolo d’Isola production plant

2002

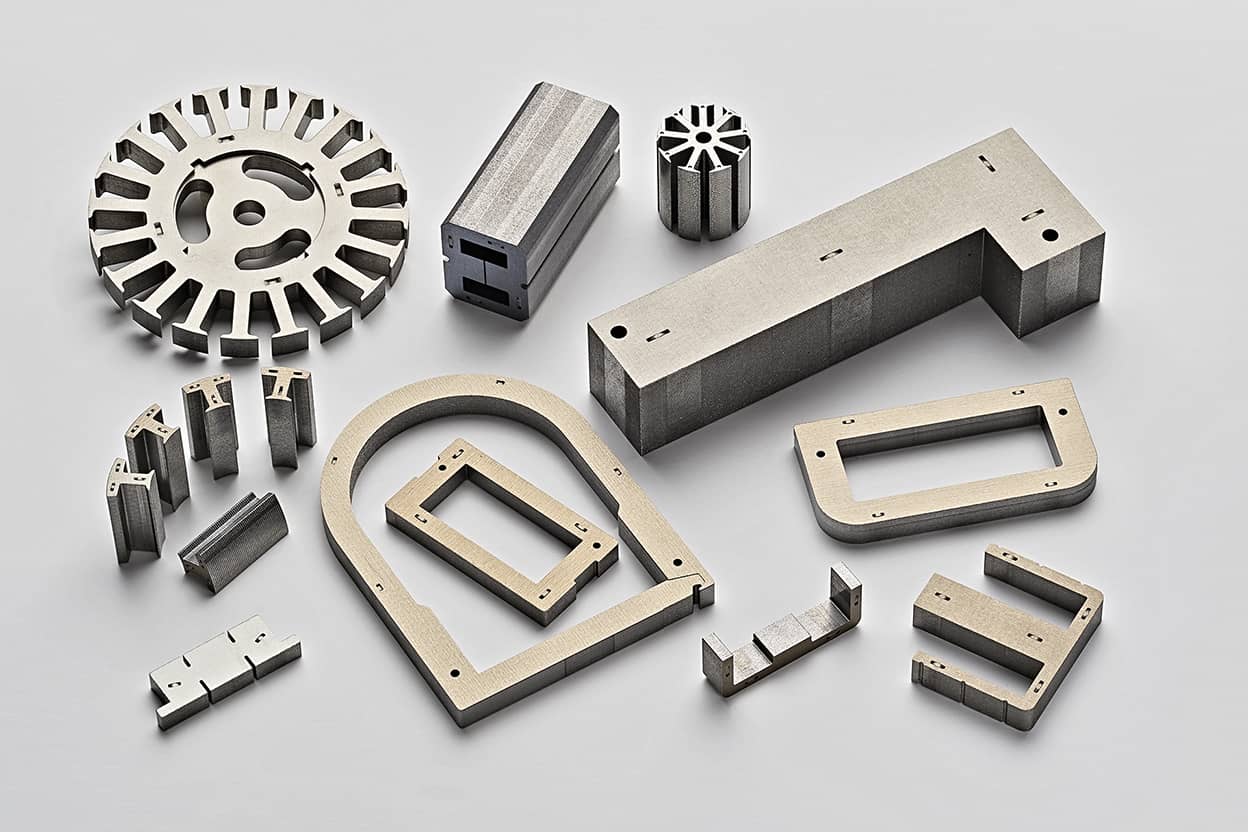

Acquisition of Aldeghi, a company specialising in the construction of moulds, tooling and high-precision mechanical parts

2005

Mollificio Fede, a company producing extension, torsion, double-torsion and compression springs and special springs, joined the Group

2006

Incorporation of Springfix Hungary Kft

2015

The third generation of the Sangalli family joined the Group

2017

Mario Sangalli succeeded his father as President of Mollificio Sant'Ambrogio. Over the years the company had greatly diversified its range of products, and springs no longer represented the major output of the Cisano Bergamasco manufacturing site. For this reason, the company name was changed to M.S.Ambrogio, maintaining continuity with the past, where M and S refer to the initials of the two founders.

2021

Acquisition of a production plant in Auburn, then named M.S.A. North America.

Acquisition of Rapitech, a company producing metal parts for quick assembly.

Acquisition of Rapitech, a company producing metal parts for quick assembly.

2022

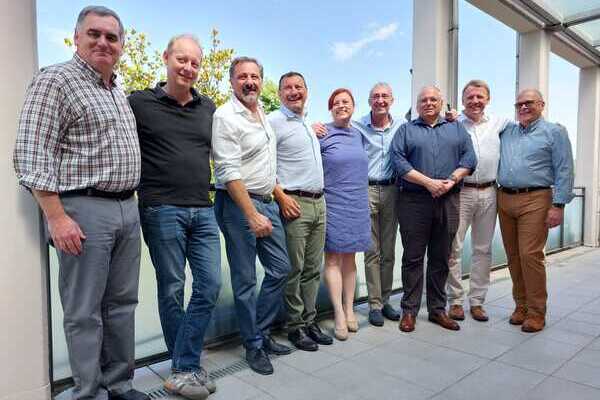

First Corporate Steering Committee in Italy.

2023

Expansion of production plants in M.S.Ambrogio do Brasil (extra 3,500 sqm) and Springfix Hungary (extra 1,550 sqm)